Pentair SuperFlo VS vs Hayward Super Pump VS: Choosing the Best Variable-Speed Pump for an Inground Concrete Pool

Homeowners planning or renovating an inground concrete pool need a pump that balances flow, energy use, and reliability. Two common choices are the Pentair SuperFlo VS and the Hayward Super Pump VS. This guide explains how variable-speed pumps differ in real-world performance, how to size and program a pump for a concrete pool, and what to watch for when comparing models so the final equipment selection reduces operating costs and supports long-term pool health.

Why pump selection matters for a concrete pool

Concrete pools typically require robust circulation to keep water chemistry stable and filtration effective. Pump selection affects:

- Operating cost — electricity use can be the biggest annual expense for pool equipment.

- Filtration performance — correct flow rate through the filter and heater ensures efficient cleaning and safe sanitation.

- Equipment life and noise — variable-speed motors can run quieter and reduce wear if paired properly with plumbing.

- System compatibility — pump voltage, plumbing diameter, and automation integration must match the rest of the pool equipment.

Quick comparison: flow versus power

Variable-speed pumps deliver a spectrum of flow and power consumption depending on motor speed and plumbing restrictions. When comparing models, homeowners should focus on the pump curve across low, medium, and high speeds rather than only the maximum flow.

- Low-speed operation is where most energy savings occur because water resistance increases sharply with flow. A pump that delivers adequate circulation at low RPMs will usually cost less to run daily.

- Mid-speed operation is typical for filtration cycles. Efficiency here determines routine electricity use.

- High-speed operation is used for rapid water features, vacuuming, or fast turnover. Maximum flow and peak power matter only for short-duty tasks.

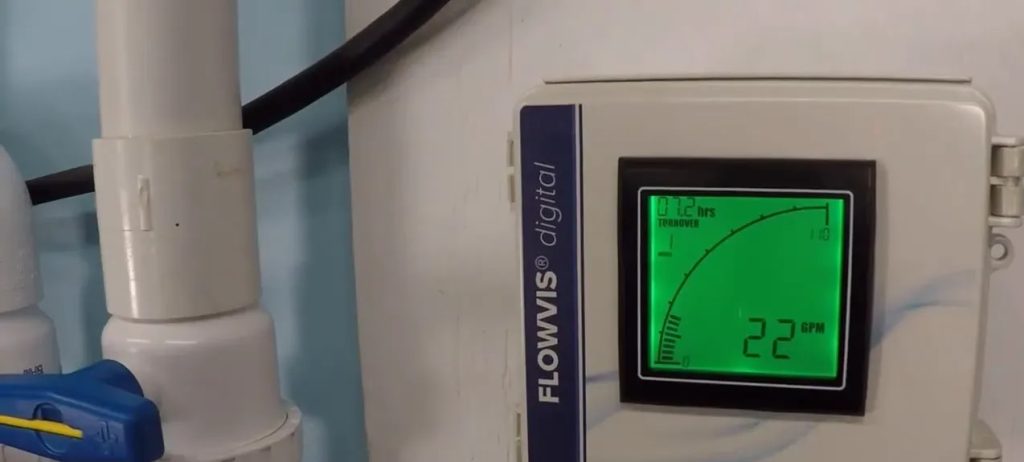

Below are example performance points representative of mid-size variable-speed pumps on a 2-inch plumbing system with a cartridge filter. These values illustrate how flow rises with speed while power consumption can increase disproportionately.

- Low speed: 15–30 gallons per minute (gpm) using roughly 30–130 watts

- Mid speed: 35–75 gpm using roughly 130–900 watts

- High speed: 75–100+ gpm using 1.3–2.2+ kilowatts

How to pick the right pump for a concrete inground pool

Choosing the right variable-speed pump means matching the pump to the pool system, not buying the highest-flow model. Follow these steps:

- Calculate desired turnover rate. Most homeowners aim for a full pool turnover every 6 to 12 hours. For a 20,000 gallon concrete pool, a 10-hour turnover requires 33 gpm. Use conservative estimates for gutters, spa returns, and water features.

- Measure system head. Total dynamic head (TDH) accounts for suction and return plumbing, filter resistance, valves, heaters, and elevation changes. Specify TDH to compare pump curves from manufacturers.

- Match pump curve to required flow at measured head. Select a pump that hits the target flow at the lowest possible power draw.

- Confirm electrical compatibility. Decide between 115V and 230V and ensure the home’s wiring, breakers, and disconnect meet local code and the pump’s requirements.

- Program multiple speed schedules. Use low speeds for filtration, higher speeds for cleaning and features, and short maximum-speed cycles only when needed.

Estimate annual operating cost: a simple example

Energy cost depends on kW draw, hours per day, and local electricity price. Example calculations show how much difference a pump’s efficiency can make.

- Assume electricity cost = $0.30 per kWh

- Filtration run time = 8 hours per day

- Example pump A draws 1.31 kW at a higher-speed cleaning cycle but typically runs at 0.87 kW during daily filtration.

Annual cost = kW × hours/day × days/year × $/kWh

Example: 0.87 kW × 8 hours × 365 × $0.30 ≈ $763/year

Running the pump at a lower, more efficient speed during filtration can reduce this figure substantially. A pump that can maintain the required turnover at lower RPMs will have lower annual operating costs.

Practical installation and selection checklist

- Plumbing diameter: Use 2-inch or larger suction and return lines where possible to lower head loss and allow lower pump speeds to deliver required flow.

- Filter compatibility: Confirm the filter’s maximum recommended flow rate and observe pressure gauges during testing.

- Electrical standby draw: Some pumps draw more idle power to power electronics. Lower standby draw reduces total energy use.

- Noise: Variable-speed pumps will be quiet at low RPMs; consider location and sound attenuation if equipment pad is near living spaces.

- Automation and control: Ensure the pump supports the pool automation system or can be programmed for time-of-use rates to save money.

- Warranty and service network: Confirm warranty terms and local service availability for the selected brand.

Common mistakes and pitfalls

- Sizing by maximum flow alone. Choosing the pump with the highest top-end flow often leads to higher energy use; focus instead on the pump curve at the pool’s TDH.

- Ignoring plumbing restrictions. Narrow pipes, many fittings, and ball valves increase head and reduce efficiency. Right-size plumbing first.

- Running at high speed continuously. Max speeds should be used briefly for vacuuming or features. Continuous high-speed running wastes electricity and stresses equipment.

- Not accounting for filter pressure. A dirty or undersized filter increases head and power draw; maintain filter elements and choose the correct filter size for the pump.

- Neglecting idle power. Some variable-speed pumps have a higher baseline electrical draw to power displays and Wi-Fi; check standby watts when comparing models.

Recommendations for Southern California concrete pool owners

In hot, sunny climates where pools operate year-round, energy efficiency and durable equipment matter more than minimal initial cost. For inground concrete pools, the following approach produces the best long-term value:

- Choose a variable-speed pump and program a multi-speed schedule: low-speed filtration for most of the day and short high-speed cycles only when required.

- Prioritize pump curve data over marketing flow numbers. Select the pump that meets required flow at the lowest possible input power at the system’s measured head.

- Invest in proper plumbing and filter sizing during construction or renovation to maximize efficiency and minimize required pump speed.

- Consider time-of-use electricity rates and schedule the highest-demand cycles when rates are lowest or run during off-peak hours.

Maintenance tips to preserve pump efficiency

- Keep skimmer and pump baskets clean to reduce suction restriction.

- Maintain cartridge or DE elements per manufacturer guidance to avoid elevated filter pressure.

- Check shaft seals, bearings, and strainer lids for wear and leaks.

- Monitor electrical connections and vibration; address unusual noise promptly.

FAQ

Which is more energy efficient for daily filtration: Pentair SuperFlo VS or Hayward Super Pump VS?

How many hours a day should a concrete pool pump run?

Can a smaller pump save money long term?

Should an inground concrete pool always use 2-inch plumbing or larger?

Related resources and next steps

Homeowners considering a new concrete pool or equipment upgrade in Southern California can find planning and construction guidance at Werth Builders: https://werthbuilders.com. For details on custom concrete pool construction and services, see the custom pools page: https://werthbuilders.com/services/pools/

Working with an experienced local contractor ensures system head is measured, plumbing is sized correctly, and a variable-speed pump is programmed to minimize energy use while maintaining water quality.

Summary

Variable-speed pumps offer the best path to lower operating costs and quieter pool systems when matched correctly to an inground concrete pool. Evaluate pumps across the full speed range, confirm compatibility with the pool’s plumbing and filter, and size equipment using measured total dynamic head. Prioritize circulation efficiency, proper programming, and routine maintenance to protect the investment and keep annual energy costs under control.

Ready to Transform Your Backyard?

Get a free consultation and estimate for your custom pool, spa, or outdoor living project. Serving Huntington Beach & Orange County.